1、Feature

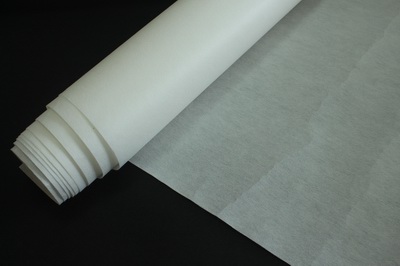

★Heat-resistant. Cooking oil filter paper can soak in the 200 degrees beyond 15 days, and the strength of filter paper not to fall significantly

★High average void ratio. It can void particle impurity above 10 micron, make frying oil be limpid and transparent, and hit the mark of filter the suspended solids in the oil.

★High air permeability. It makes lipin material with high viscosity pass successfully, and with fast speed.

★High wet and dry strength. The bursting strength up to 350KPa, the tension stress of vertical and horizontal is 65N and 45N

2、Advantage

Removing the cancerogenic substance (aflatoxin) in the frying oil

Removing the peculiar smell in the frying oil

Removing the free fatty acid、peroxide、high molecular polymer and particle impurity in the frying oil

Removing the sallow color in the frying oil, improving the oil cast and making the oil color to be the original color

Controlling the oxidation and rancidity reaction, it not only can improve the quality of frying oil, but improve the hygienic quality and extend the shelf life of fried food

Under conforming to the food sanitary regulation, making full use of dried oil to bring a better economic benefit to the enterprise, the cooking oil filter paper widely used in various frying oil filtering machines

Usage: Be suit for filter crude oil and petroleum products in the producing of edible oils and vegetable oil, and the working process of fried food, such as fried chicken, fried fish, fried nuts、 chips、instant noodles、caramel treats and prawn slices

typical application area of filter material

*Food and beverage: the purification treatment and CIP filtration of beer, wine, fruit wine, sake, yellow rice or millet wine, juice, bottled water, tea drinks, soymilk, dairy products, edible oil, vinegar, aginomoto

*Bioengineering and medicine: transfusion (LVP & SVP) pharmaceutical water, process gas, biological products plasma and serum, various medical intermediate, acridine, solvent filtration, CIP filtration, fermentation cylinder air suction and end gas degerming filtration

*Petrifaction and chemical: the fluid purification treatment of lubricating oil, jet fuel and various oils, catalysts, mucilage glues, polymers, resins, hydrogen peroxides and chemical fibers, the recycling and separation of valuable chemical intermediate goods and chemical product

*Automobile making: the gas purification of electrophoretic paint, pre-conditioning fluid, finish, ultra-filtering water, engine crankshaft manufacturing cooling liquid, spray water, process gas and spray booth for paint spraying

*Petroleum and natural gas: the separation and purification of natural gas and refinery plant, gas station CNG filtration, amine desulfuration and dehydration solvent filtration, oilfield flooding and well completion, well repair and acidize liquid filtration

*Electron and electroplate: the treatment of IC, kinescope, liquid crystal display, lithography machine, optical disk, copper foil and other micro-electronics and electronic products, electroplate liquid, the purification of process gas and the gas filtration in the clearing room

*Coating, oil paint and printing ink: emulsion varnish, oil paint raw material and solvent filtration, printing ink, stamping ink and additive filtration

*Other industries: nuclear power,thermal power and effluent filtration, photographic film manufacturing technique liquid filtration, daily chemical liquid and gas purification, machining and refrigeration industry filtration, the liquid purification of spinning, printing and dyeing and papermaking industry